The Secrets Behind Getting Good Packaging Designs That Overseas Buyers Should Know

Oversea buyers are often challenged by the dilemma of keeping product packaging cost down and of ensuring sufficient protection for products during transportation. One of the last steps on the manufacturing side, package the final products is often a neglected process by both the buyers and the manufacturers. A well-designed product packaging can not only minimize damage during cross-continental transportation, but also attract end-consumers when they are choosing among various brands of similar product in front of the shopping aisle. Since packaging is such a crucial step, how can oversea buyers ensure their purchased goods received the added-value from the process?

As we research on several well-reputed suppliers in different industries, we found out that suppliers who can meet three vital fronts will be more likely to provide additional value on their products’ packaging. One factor is whether the supplier owns an independent packaging design team; another factor is whether its packaging team has sufficient experiences on packaging process; the last one is whether the supplier can execute according to desired standards. Suppliers who can meet the three vital fronts can help buyers to minimize damages during transportation and can even support brands to build consistent and differentiated brand image on market by helping design the product packaging and execute the design according to market requirements. To better understand the packaging process, we visited Shanghai Wellmax Lighting Industry Co. (WELLMAX), the renowned “LED Bulb Expert” and the top exporter of LED bulbs in Shanghai. With 30 years’ experience in lighting industry, WELLMAX has sold cumulatively 900 million bulbs worldwide. Equipped with professional teams of engineers, WELLMAX served over 200 brand partners, with whom building long-term stable business relationships. The following introduces some key points of WELLMAX’s one-stop packaging process.

WELLMAX packaging design

Customized packaging for different product models

The paper pallet designed to stabilize lamp body in the inner box is to protect the base of a LED bulb from the potential damages during the loading, unloading and transportation process. To maintain cost competitiveness at the same time, engineers also need to consider the size and weight of different models and decide which models should include the paper pallet and which ones are not required to include one. For example, the packaging that WELLMAX specially designed for small lamps with better quality paper materials are solid enough to hold and protect lamp body inside without using a paper pallet, while the larger bulbs such as A70 and A95 require a paper pallet to better protect the products.

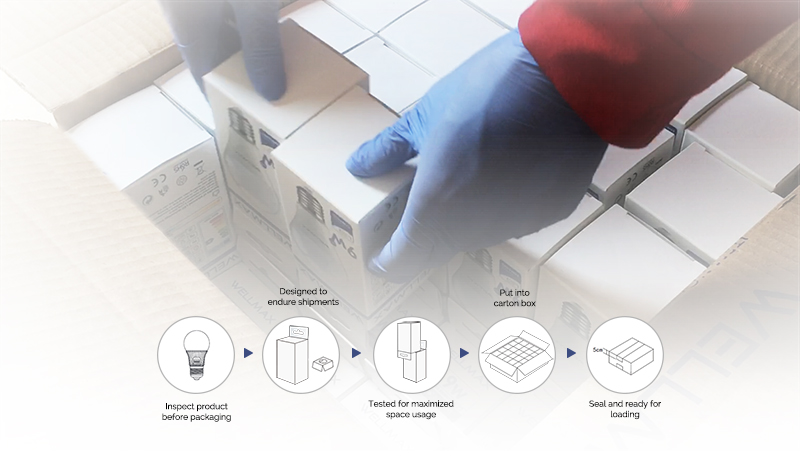

Standardized packing method

Each inner box is neatly stacked in corresponding carton. WELLMAX designers designed the inner boxes with hanging hold not only for easier display in store but also for added protection while the products are in the carton. Products are placed in a way that each hanging holes interlock with each other to ensure stability within a carton to prevent products from shaking and knocking against one another.

Calculated carton dimension to avoid overweight

An overweight carton can damage products inside. Many manufacturers will, in order to cut cost, compromise product safety for saving on packaging material and having more room in containers. WELLMAX packaging engineers calculate reasonable volume of carton boxes for different product models. Normally, one carton for A50 can pack 100pcs bulbs, and for larger type of bulbs a carton should not be designed to hold more than 50pcs. Any requirements for bigger boxes or more products will post risks to workers in handling the goods; any mishandling will be likely to hurt workers as well as damaging the products.

Drop test

Every packaging design must be tested by WELLMAX quality inspectors through a series of drop test. A full carton will be tested to drop a total of 10 times from a various height according to the “One corner, Three edges, Six faces” principle. After the drop test, WELLMAX quality inspector will grant three different statuses to the packaging:

- Pass: No damage or breakage on product and package. No functionality issues found with the product.

- Pending: Packaging including outer carton, inner boxes or unit package are somewhat damaged, but the product remains intact. It is up to the buyers whether it is acceptable.

- Failed: Product inside is damaged or broken, sharp edges or small loose parts are revealed after the test.

Although the final step of the product manufacturing, product packaging is a miscellaneous but critically important step. It is a shame if good quality products are damaged during transportation or gone unnoticed on the shopping aisle because of improper packaging design. Having checked out the above steps of WELLMAX packaging process, you can see that to do product packaging well is also not as easy as one may imagine. Every stage of packaging requires precision and professionalism to ensure final execution. WELLMAX has teams consisting of senior packaging engineers with over 8 years of experiences in packaging design, therefore it can customize packages that not only are compliant with different market standards but also showcase the products inside to the end-consumers effectively through optimized packaging design. WELLMAX deploys professional and systematic management on production process, helping buyers cut down the total purchasing cost in cross-border trade and win an competitive edge on their market. That’s why over 200 oversea brands from different countries choose WELLMAX as their consistent reliable business partner.

Related news

1 week ago · 5 mins read

1 week ago · 5 mins read

2 weeks ago · 5 mins read

2 weeks ago · 5 mins read